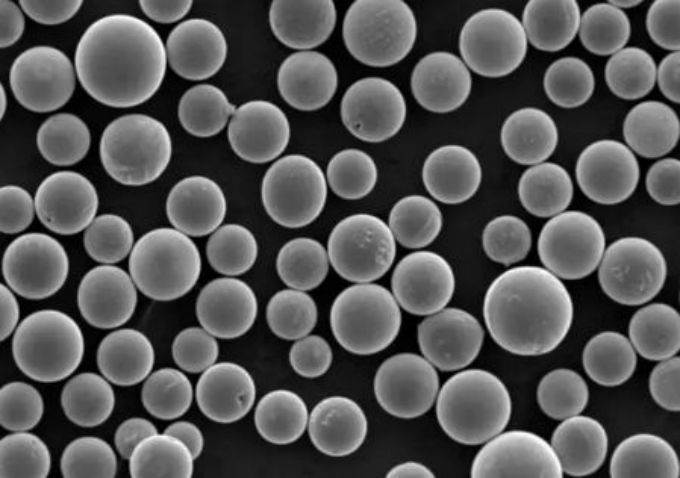

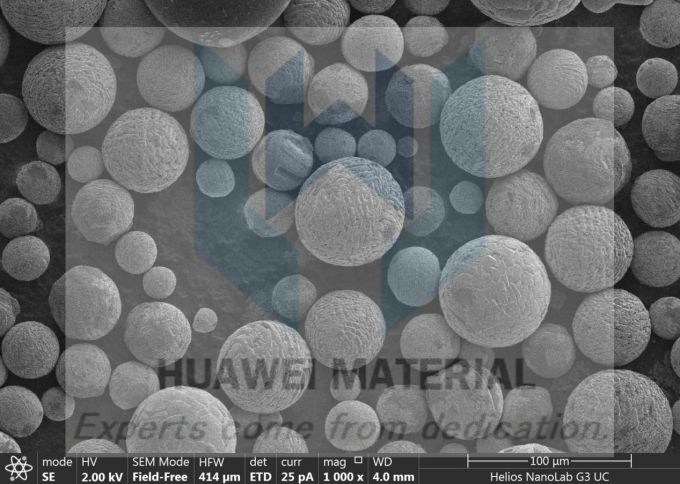

1. Spherical titanium powder (Ti powder)

Spherical titanium powder has the characteristics of high sphericity, high density, low oxygen content, good fluidity, and uniform particle size distribution. It can be widely used in 3D printing materials, aerospace, spray coating and other industries.

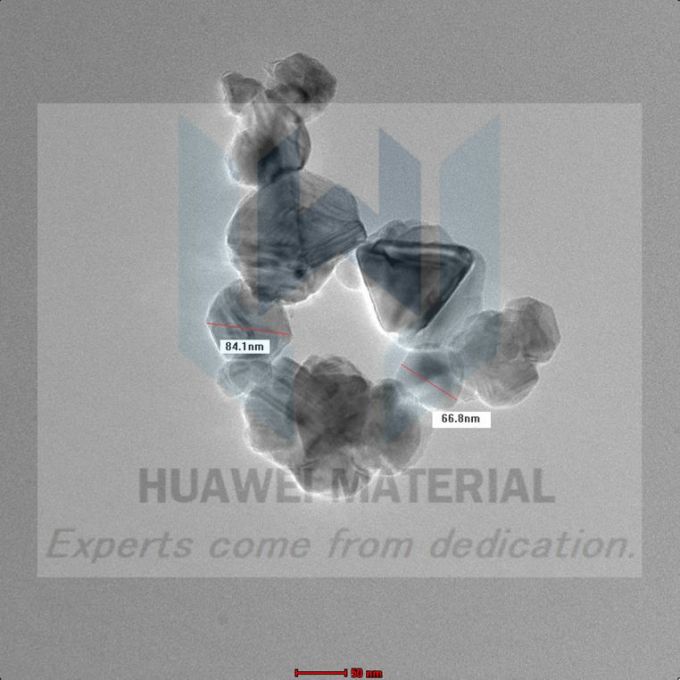

2. Zirconium boride (ZrB2)

Zirconium boride has the characteristics of high temperature resistance, oxidation resistance, high strength, high hardness, good thermal conductivity, and good toughness. It also has the characteristics of efficiently absorbing visible light, reflecting infrared rays and energy storage. It is widely used in carbon-carbon composite materials, cemented carbide, thermal insulation and temperature-regulating textiles, fine ceramics and high-temperature coatings.

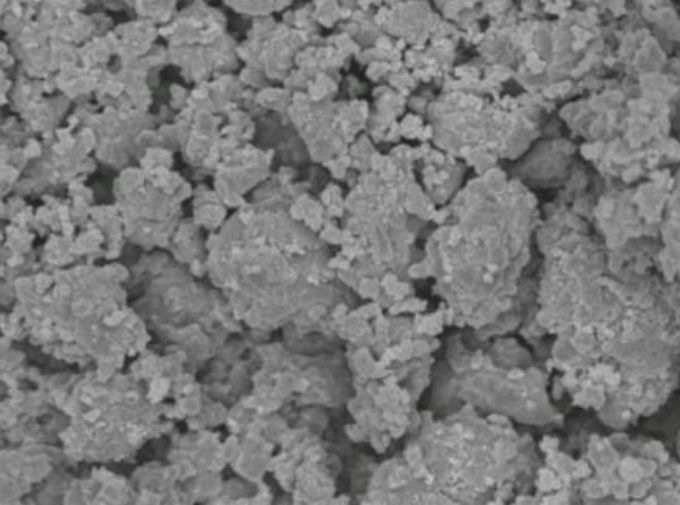

Titanium carbide (TiC) has a high melting point, high hardness, and good chemical stability. It is mainly used to make cermets, heat-resistant alloys and hard alloys. Multiphase materials prepared with titanium carbide have a wide range of applications in the fields of mechanical processing, metallurgy and minerals, aerospace, fusion reactors, etc.

4. Nano-spherical silicon powder

Nano-spherical silicon powder has excellent dielectric properties, low thermal expansion coefficient, low thermal conductivity and corrosion resistance. It is one of the most important and key raw materials in the high-tech field. It can be widely used in semiconductors, batteries and alloys.